by Marcelo Pinto July 8th 2012

Italy’s cozy town of Parma has been known for Prosciutto di Parma for over 2,000 years. The secret recipes of these air-dried hams have changed hands throughout history within families. It is a product of man’s passion and skill, combined with nature. The Parma ham has put Italy on the global gastronomic map due to its uniqueness.

The micro-climate of Parma is very conducive to the ham production, with its dry and airy summers and cold winters. Humidity levels are moderate, while the air carries the smell of the sea and chestnut trees. To maintain the high quality of Parma ham, it must be kept away from variations in climate. The production area is restricted to a height less than 900 meters above sea level on the Parma hills, since regions lying above this height face a very cold and long winter. The production area must also be 5 kilometers away from the humid and foggy Via Emilia along the Po River. The limits are the Enza River on the east and the Stirone River on the west, which bring in fragrant sea breezes that roll down into Parma valley.

The curing of the ham is crucial to its quality. It is carried out by natural methods, even though they take as long as 12 months and require immense care, patience and skill. Traditions have evolved over time, with more refined breeding and farming procedures. This has made the pork sweeter and more tender.

Knowing the process of curing the meat is not enough. The ‘master salters’ from Parma have learned from their ancestors how to identify good pork legs, trim the hams by hand and apply salt properly to ensure outstanding quality. The latter is a deciding factor for determining the quality of the curing process and retaining the sweetness of the ham.

The Consorzio del Prosciutto di Parma or Parma Ham Consortium was established in 1963. It started with 23 members and has now 180 members. Their mission is to maintain the quality and tradition of Parma ham by sticking to natural methods; salt and air are the only additives. With records kept regarding the origin, birth date and breeding method for each pig, all production stages are closely monitored by the Istituto Parma Qualita, an independent certifying body, in keeping with the rules of the Consortium. A special law was even laid down by the Italian government. The Protected Designation of Origin (PDO) has been recently awarded to Parma air-dried ham, giving it copyright over the name.

The pigs from which Parma ham is made have to be heavy and their meat must be soft, yet firm. They have to be born and raised only on an authorized breeding farm in one of the 11 designated Northern and Central regions of Italy. Traditionally they are fed whey, a by-product of Parmigiano-Reggiano cheese. This imparts a unique flavor to their meat.

The hams are exposed to constant cold and humid conditions for 100 days, after which they are kept in large maturing rooms for 3 months. This way they are protected from the sun. The windows are constantly opened and closed for circulation of the countryside air. In the seventh month, a mixture of pork fat and pepper called sugnatura is hand-applied onto the open surface of the meat. This is meant to protect and soften it. The hams are then put in cantina or cellars for at least 5 months, so that they can slowly dry under close supervision. The producers are trained and experienced in detecting any quality defects by the sense of smell. The spillatura is a horse bone needle which is used to check the curing outcome, before assigning the precious label of ‘Parma Ham’.

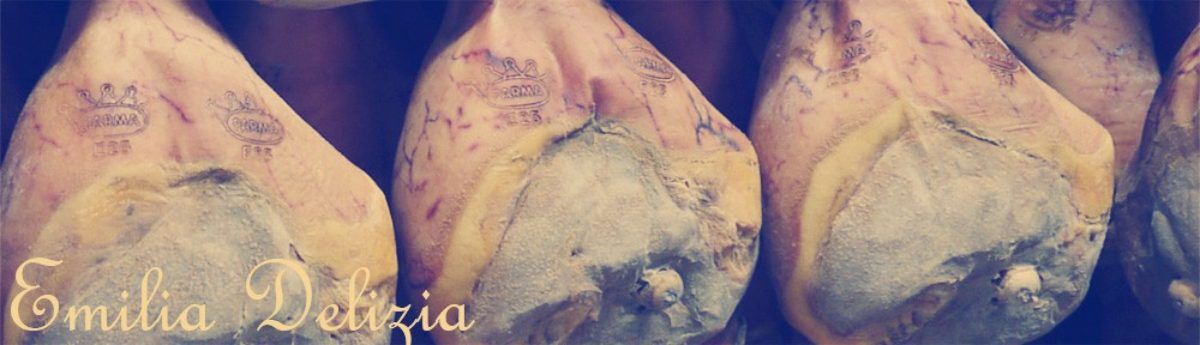

The ham gets several imprints in the various stages of production. The breeder makes a permanent tattoo onto the hind legs of the piglets, consisting of the month of its birth and the identification code of the farm. At the slaughterhouse, the initials PP (for Prosciutto di Parma) are fire-branded onto the pork legs if they are worthy enough to be sent to the production line as Parma Ham. At the entry to the curing house, the legs are stamped with a metal seal having the Consortium code and the month and year when curing started. After passing all verification and regulatory tests, the legs are finally fire-branded with the 5-pointed Ducal Crown of the Consortium, along with the name, ‘Parma’. The producer’s code is added under the crown. This is the guarantee of a 100% natural and light Parma ham that is a product of age-old traditions.

A slice of Parma ham has a delicious country aroma; it is succulent and thin, with a distinctive salty-sweet taste. It is best enjoyed stand-alone and no other air-dried ham comes close to Parma Ham in bringing you this divine gastronomic experience.